Day :

- Petroleum Geology

Chair

Ailin Jia

Research Institute Research Institute of Petroleum Exploration and Development, CNPC, China

Session Introduction

Nejat Rahmanian

University of Bradford, Bradford, BD7 1DP, UK

Title: Impact of Impurities on Formation of Carbon-Dioxide Hydrates

Biography:

Dr Nejat Rahmanian is currently a senior lecturer in Chemical and Petroleum Engineering and MSc/MEng Program Leader in the area of Chemical and Petroleum Engineering in University of Bradford. He has over 18 year’s experiences in both academia and industry. In academia, he worked in Universities of Tehran and Shiraz (Iran), Universiti Teknologi PETRONAS (Malaysia). Nejat has hold four patents, published three chapter books, about 60 journal articles and refereed-conference proceeding. He is actively involved in research in the area of oil/gas processing. His current focus is on CO2 capture and storage, process modelling and simulation of hydrocarbon processes. He has ongoing research collaborations with industries and academic institutions in the UK, Canada, the Netherlands, India, Iran, Oman, Saudi Arabia and Malaysia focusing on hydrocarbon processing and carbon capture and storage. In industry, he worked continuously nearly 8 years in Petropars Limited Company as a Process and later on as Senior Process Engineer for development of South Pars Gas Field Development, the biggest gas retograte-condenaste reservoir in the world. During his working period, he worked closely with International Engineering and Construction Companies in Malaysia, Japan, South Korea, and UK for development of the field. He also collaborated part time with national petrochemical companies.

Abstract:

The continued rise of CO2 emissions threatens life on Earth, through warming the planet. Carbon Capture and Storage (CCS) is an effective method in reducing CO2 emissions, thus over time, inhibiting the effect of global warming. One of the major challenges that face the transportation process, an intermediate stage between capture and storage, is potential flow assurance issues, especially hydrate formation due to the presence of impurities such as N2 and H2O. If the conditions within the pipeline are at a high pressure and low temperature, hydrates could form. Hydrate formation, which is the physical combination between a gas molecule and water molecules, could cause pipe blockage and therefore, stop the high-CO2 mixture being transported to its storage location.

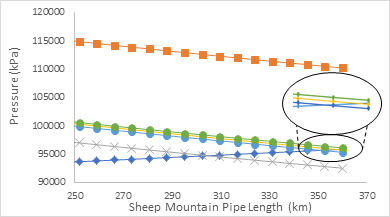

This study aimed at investigating the impact of impurities on the formation of CO2 hydrates, whilst simultaneously, considering the vapour-liquid equilibrium (VLE) phase envelope. Initially, a sensitivity analysis on binary and tertiary systems was conducted, based on the impurities most commonly encountered in CCS. Where from here, investigation into two case studies (Cortez and Sheep Mountain Pipeline) was conducted. The results from the binary analysis showed H2S caused a significant expansion of the hydrate stability zone (HSZ). The presence of the impurities, COS, SO2 and NH3, caused the opposite effect to what was found with H2S. Each impurity caused an effect on the VLE phase envelope with H2 and N2 causing the most significant expansion. The tertiary system sensitivity analysis showed there was a clear interaction between H2S with Ar, O2 and CH4. Analysis into the case studies showed the presence of H2S reduced the hydrate formation pressure thus increasing the likelihood of hydrate formation. This was proven to be counteracted with the presence of either COS, SO2 or NH3, where they increased the hydrate formation pressure.

M.A. Rahman

Memorial University of Newfoundland, St. John’s, NL, Canada

Title: Experimental Investigation of Pressure Drop for Gas / Shear Thinning Fluid Flows in a Horizontal Pipe

Biography:

Rahman's background in multiphase flow experiments and CFD of both academic (fundamental) and industrial (applied) research contributions have been documented in more than 50 refereed journals and conference proceedings. In recognition of his high-quality research endeavors, Rahman has been awarded several multimillion-dollar grants from organizations such as the Natural Sciences and Engineering Research Council of Canada and Newfoundland Research & Development Corp. He has been involved in a number of research collaborations with companies, including Intecsea, Husky Energy, Syncrude Canada, GRI simulations, C-Core and Coanda Research & Development Corp.

Rahman was a postdoctoral fellow in 2012 in the School of Mining and Petroleum Engineering at the University of Alberta. He also worked as a postdoctoral fellow in 2011 in the Department of Chemical and Materials Engineering at the University of Alberta. He earned his Ph.D. from the University of Alberta in 2010 and his master's degree from Dalhousie University (Canada) in 2004. Rahman has successfully supervised a number of postdoctoral fellows, graduate students, research associates and undergraduate students. He is the recipient of a best teaching award from the University of Alberta in 2009. He is also involved in with a number of professional organizations, including SPE, ASME and CSME. He is a registered Profession Engineer in Alberta, Canada.

Abstract:

The objective of the study focuses on gas/non-Newtonian liquid horizontal flow in a pipeline. The gas and the liquid flow rates were varied over a wide range of flow conditions. The flow rate of the non-Newtonian liquid ranged from 0.023 to 0.115 m3/s, while that of the gas ranged from 0.023 to 0.160 m3/. The experiment was conducted to determine the pressure drop using a transparent pipe of 76.2 mm diameter and 2.44 m long horizontal pipe. Xanthan gum solution was used to simulate non-Newtonian fluid. The pressure drop gradient model of Lockhart-Martinelli as modified for gas/shear thinning fluid flow. The theoretical predictions of pressure loss were compared with the experimental data for air/shear thinning fluid flow results. From the experimental work, it was observed that the pressure drop was directly proportional with the concentration of Xanthan gum (shear thinning fluid). The flow regimes of bubbly, slug, plug and wavy flow were also captured by a high-speed camera.

Yunsheng Wei

Research Institute Research Institute of Petroleum Exploration and Development, CNPC, China

Title: Current technologies and prospects of shale gas development in China

Time : 11:40-12:15

Biography:

Dr. Yunsheng Wei began his professional career at RIPED in 2006, having abundant experience in unconventional gas development about 10 years. He has made great contributions to improving reservoir engineering, especially in tight gas and shale gas. He has published more than 30 papers in reputed journals and has been serving as an editorial board member of several gas engineering journals.

Abstract:

Shale gas in China has realized the great-leap-forward development because of the significant strides of development technique for marine shale resource, becoming the second largest shale gas producer only to USA. At present, a complete technique series for the development of shale resource buried less than 3500m (<3500m) has been established by operating technique research and field trail, including five main key techniques of geological evaluation, optimum & fast drilling, multistage hydraulic fracturing, productivity evaluation, and development parameters optimization:

(1) The integrated technique of geophysics data interpretation and geological evaluation to identify high-quality shale interval provides a guidance for the target optimization of drilling horizontal well and the mass arrangement of multi-well.

(2) Optimum & fast drilling technique is realized by incorporating rotary steerable drilling and factory operating pattern, contributing to shorten single-well drilling cycle by 50%.

(3) Volume fracturing technique integrating low-viscosity slick water, low-density proppant, zipper-style fracturing and factory operating pattern, is conducted to enhance fracturing efficiency by 50% and improve testing production rate to 20×104m3/d.

(4) Productivity evaluation technique incorporating multi-scale fracture network and stochastic simulation is performed to analyze production performance with probabilistic forecasts.

(5) A systematic optimization of fracturing parameters and well spacing is established by type curve matching, production performance modeling, and analogy with exploited shale field in North America.

At present, shale resource in China has not been fully exploited besides the marine shale resource (<3500m). It would be the future development trend to enhanced ultimate recovery of shale gas (<3500m). Moreover, 2/3 recoverable resource is stored in the formation (>3500m). With the further process of development technique for marine shale, shale gas is expected to the single type of gas reservoir contributing to the highest annual production rate in the near future

Kjeld Bokstijn

Fluor Corp

Title: Integrated consulting services for rich gas production plan from mature fields

Time : 12:15-12:50

Biography:

Kjeld Bokstijn is a process engineer that has been active in the industry over the last 22 years, working in production and engineering functions in The Netherlands, the United States and Spain. He holds a BSc. and MSc. in Chemical Engineering and is currently employed by Fluor as a process director working on projects mainly in the chemical, petro-chemical, refining and power generation area. However due to the interfaces between the gas plant and the petrochemical units consuming the NGL feedstock from these, he has become involved in this NGL recovery and gas-production feasibility study. Fluor´s Energy and Chemicals division, an international engineering contractor, is involved in all these areas from upstream, midstream, downstream, petrochemical, chemical and energy business and as such can bring together multi-functional teams to work on these diverse projects offering these kind of interesting assignments to their personnel.

Abstract:

Fluor was approached by a client requesting a feasibility study for a rich gas field development and debottlenecking the offshore and downstream NGL facilities. Fluor is primarily involved with gas/oil production, transportation, and gas processing/NGLs facility design and does not perform reservoir assessments in-house. In this case, Fluor and the client worked out an integrated solution with a subcontracted reservoir engineering effort to assess current in place gas/liquid volume that could be produced from the fields to support the desired gas feed rate for the offshore and onshore NGL facilities our client wanted to debottleneck.

The reservoirs have been evaluated to assess the original hydrocarbons in place for each reservoir, material balance results have been compared to the current reservoir pressures to validate the reported gas production and gas re-injection values over time, and to obtain the current in place volumes. Based upon the current gas in place and the reservoir pressure profiles, a well development program was prepared to support the production plan. As part of the reservoir assessment it was found that the current in place gas/liquid volume in the reservoir does not support the clients originally proposed production plan. Hence as a result of these feasibility study findings the client postponed the offshore development and NGL recovery facilities revamp scopes.

Overall Fluor has been able to successfully and effectively coordinate the different interfaces between the client´s intended production plan and availability of data of the existing reservoirs to the reservoir engineering consultant and from the output of the reservoir engineering study back into the data needs for the required production to identify the potential offshore development and downstream NGL processing facilities’ revamp.

Faraj Ahmad AL-Sulaiman

chief geologist in the Field division of petroleum engineering department for the North Oil Company, Ministry of oil, Kirkuk, IRAQ

Title: Geologic evaluation of Kirkuk underground storage project NE Iraq

Time : 12:50-13:25

Biography:

Faraj A. Al Suleiman, is chief geologist in the Field division of petroleum engineering department for the North Oil Company, Ministry of oil, Kirkuk, IRAQ, He received his BSc degree from Mosul University in general geology in 1982, and received MSc and PhD degree in structural geology from Baghdad university, in 1989 and 1998 respectively, since 2000 he joined North oil company as supervisor for logging operation and interpretation. In addition to work in North Oil Company, he lectured in kirkuk and Tikrit universities.

Abstract:

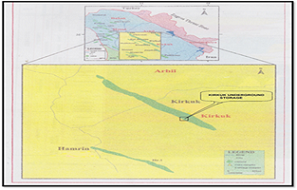

Storage of liquids and gases in solution mined salt caverns was reportedly first in Canada in the early 1940 s during world war. Storage in the salt caverns of liquid petroleum gas (LPG) and other light hydrocarbons spread rapidly in the early 1950s in North America and several European countries. Storage of crude oil reportedly occurred first in England, also in 1950s during the Suez crisis. Natural Gas Storage followed the storage of liquid hydrocarbons by about decade in the U.S.A. and Canada,(Dreyer,1920).Kirkuk underground storage project locate on the southern west limb of Kirkuk anticline near Kirkuk city, North Iraq,(fig-1).In 1978 eight wells were drilled for the purpose of LPG storage ,five wells of them(2,5,6,7,8) were selected for leaching operations as the thickness of salt layer in these wells was suitable to create cavern of salt and economical size.

Geologic evaluation of the Kirkuk underground was conducted by comparison of the geometric properties of the cavities derived from two surveys running during 1989 and 2015.the vertical cross sections of the cavities show that most cavities have show that most cavities have irregular shape because of the presence of impurities in the salt bed that cause different leaching velocities in different directions .the relationship of the cavity roof with tilted salt bed was Image

Ali Qubian

TPL (RE/PE) Senior Specialist at Subsurface Team of R&T Group at Kuwait Oil Company (KOC)

Title: Development of a web portal Knowledge base EOR screening/Design expert system

Time : 14:25-15:00

Biography:

Currently a TPL (RE/PE) Senior Specialist at Subsurface Team of R&T Group at Kuwait Oil Company (KOC). Prior to this, he occupied a number of both industrial and academic positions in UK. He holds a First Class Honors BEng in Petroleum Engineering and a Ph.D in Steam-foam drive process in EOR from University of Strathclyde, Glasgow, UK. He has had over 30 years of academic, industrial and research experiences mainly associated with the upstream sector of the oil and gas industry. He is currently the EOR Cluster Leader within the Subsurface Team. The job involves advanced technology screening and implementation for relevant Reservoir subsurface challenges and adopting the most efficient and economic ones to address them. Major Area of interest: EOR, Reservoir monitoring and simulation, Uncertainty analysis, new technologies and innovation, unconventional reservoirs, and production optimization.

Abstract:

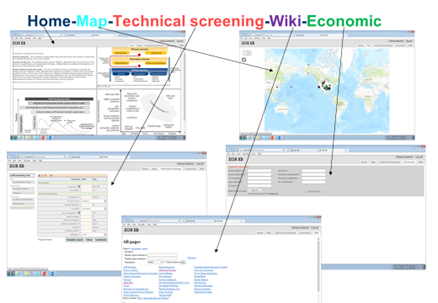

The current work is concerned with the development of a web-portal knowledge-based Enhanced Oil Recovery (EOR) expert system for screening and designing EOR process. Conducted and ongoing projects including all the spectrum of laboratories, pilot, and full-fields scale implementation need to be shared among oil and gas community for the ultimate goal of sharing of best practices, technology transfer and lessons learnt in such highly demanded area. On the other hand, on local scale oil and gas operators would benefit from such expert system in setting an informed workflow and screening/design tool aims at selecting the most appropriate. The industry is currently lacking of such system and there is no single source of knowledge on EOR technologies and their application. The industry has clearly expressed a need for an expert system to aid operators in selecting optimum EOR applications and procedures. The project creates an “enabler” for oil and gas operators and financial institutions, thus helping to popularize EOR screening as a routine aspect of field development planning even in early stages of a field’s life cycle. The EOR KB will address these technology gaps.

The ultimate aim of this industrial is to develop a computer module (expert system) in the form of web portal knowledge bases EOR system to be used as a screening /design tool for adopting the most suitable EOR. The methodology used here includes published data on completed projects and world-wide experience and expertise. Existing analytical models and correlations on the three methods (Gas-Chemical-Thermal) are used to develop the module. The web portal contents include reservoir properties, reservoir performance, operations & lessons, and costs & economics.

The system allows different scenarios to be run including cost and Net Present Value (NPV) comparison, availability of gas, CO2, Chemicals, and other commodities. It enables companies to screen and prioritize EOR technique potential as applicable to the specific field opportunities.

The developed EOR KB addresses the need for an Expert System to aid EOR decision making and will provide a comprehensive single resource for best practices, lessons learned and case histories across the EOR spectrum. In fact, the development tool adds a new customised tool to the engineers and earth scientist in general working kit including handling new technologies such as LowSal and MEOR.

Sun ke

China University of Petroleum, China

Title: The application of architectural elements analysis in characterizing complex reservoir: A case study of Yong’an town oil field, Dongying Sag, Bohai Bay Basin, China

Time : 15:00-15:25

Biography:

Sun ke, PhD. candidate, engaged in petroleum geology research, Department of Geology, College of geological science and technology, China University of Petroleum

Abstract:

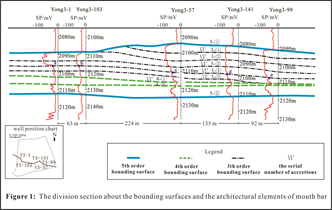

As the exploration and development of oil and gas fields gets deeper and deeper in our country, characterization of complex reservoir has become one of the most important research fields. The characteristics of complex reservoir are that rock composition is complex, space structure is complex, kind of reservoir space is various, heterogeneity is strong, physical properties is changeful et al. In view of the above characteristics, there are three problems in traditional reservoir characterization methods which is about gradation, structure and genesis. That architectural elements analysis put forward offers method and idea for solving the above problems. Compared with traditional reservoir characterization methods, the advantages of architectural elements analysis mainly display in three points: first, it can be applied to divide high frequency level of reservoir; second, it can be applied to analyze complex structure of reservoir; third, it can be applied to explain the genesis of reservoirs. The Application of architectural elements analysis in characterizing complex reservoir need to pay attention to the applicable condition of the method, the choice of the basic research unit and the relationship between architectural elements and pay zone units. This paper takes Es26 of mouth bar which belongs to the Yong3-1 fault block of Yong’an town oil field in Dongying Sag as example, combining with the advantages of architectural elements analysis and problems that should be noticed, thoroughly studies the issues on the division of bounding surface, reservoir sedimentary genesis and the distribution characteristics of oil and water, and comes to the conclusions: the original 61 layer could be divided into six times accretions of mouth bar(architectural element of 3 level),the dip angle of mouth bar accretions is between 2~3°; six times accretion of mouth bar had the characteristics of retrogradation from west to eastï¼› the oil and water distribution of 61 layer was mainly controlled by accretion of mouth bar.

Mesfin G Woldetensay

Heriot-Watt University, Dubai campus, UAE

Title: Optimal Design and Operation of Gas Processing Plant (GPP) under Uncertain Upstream Conditions

Biography:

Mesfin is currently working as Assistant Professor & Program Director of Chemical Engineering at Heriot-Watt University Dubai Campus. He was a postdoc fellow at Yeungnam Univeristy (South Korea) before joining Curtin University, Sarawak Malays as faculty staff. Mesfin has won the 2014 IChemE Malaysia Award for Research Innovation and Excellence. He also got a prize for his research being highly commended in the Petrochemical Processing Award at the 2013 IChemE Malaysia Awards for Innovation and Excellence”. He has won also the 2015 APAC-EMEA (Asia Pacific, Europe, Middle East & Africa) Honeywell UniSim Design Challenge & the 2014 Asia Pacific Honeywell UniSim Design Challenge. His current research work focuses on optimal design and operation of thermally coupled distillation unit under uncertainties. Thermally coupled distillation such as dividing wall column (DWC) has significant advantage in terms of energy saving by more than 30% compared to the conventional distillation columns.

Abstract:

Uncertainty is an inherent characteristic of any process. It may arise both from external and internal factors and has a profound effect especially for gas processing plant as its feeds are normally originated from upstream production facilities. Thus, the plant is usually subjected to continuous variations in upstream conditions, such as feed flow rate, composition, ambient temperature and pipeline pressure. These variations effects propagate throughout the plant and affect its normal operation. As a result, decision making for optimal operating conditions of an in-operating plant is a complex problem and it is exacerbated with changing product specifications and utility requirements. Moreover, the condition of feed composition is an important factor since it mainly determines what kind of process configuration to be employed for recovering natural gas liquids (NGLs). Besides, due to the number of process schemes developed for NGL recovery, it is usually difficult to select the best process scheme that can consolidate capital and operating costs within an acceptable range. In industrial practice, heuristic optimization approach based on trial and error have been employed to solve those problems. The main reason for such kind of decision is due to lack of systematic solution approach. As a result, aggressive decision may be preferred due to high profit expectation. However, this strategy will deteriorate the objective function and later leads to constraint violation. Therefore, a systematic method is required to evaluate the trade-off between profitability and reliability of holding the process constraints. The challenge here is how to find solution approaches that can incorporate all these uncertainties effect and enable us to make prior-decision for the in-operating plant.

Session Introduction

Kjeld Bokstijn

Fluor as a process director working on projects mainly in the chemical, petro-chemical, refining and power generation area

Title: Integrated consulting services for rich gas production plan from mature fields

Biography:

Kjeld Bokstijn is a process engineer that has been active in the industry over the last 22 years, working in production and engineering functions in The Netherlands, the United States and Spain. He holds a BSc. and MSc. in Chemical Engineering and is currently employed by Fluor as a process director working on projects mainly in the chemical, petro-chemical, refining and power generation area. However due to the interfaces between the gas plant and the petrochemical units consuming the NGL feedstock from these, he has become involved in this NGL recovery and gas-production feasibility study. Fluor´s Energy and Chemicals division, an international engineering contractor, is involved in all these areas from upstream, midstream, downstream, petrochemical, chemical and energy business and as such can bring together multi-functional teams to work on these diverse projects offering these kind of interesting assignments to their personnel.

Abstract:

Fluor was approached by a client requesting a feasibility study for a rich gas field development and debottlenecking the offshore and downstream NGL facilities. Fluor is primarily involved with gas/oil production, transportation, and gas processing/NGLs facility design and does not perform reservoir assessments in-house. In this case, Fluor and the client worked out an integrated solution with a subcontracted reservoir engineering effort to assess current in place gas/liquid volume that could be produced from the fields to support the desired gas feed rate for the offshore and onshore NGL facilities our client wanted to debottleneck.

The reservoirs have been evaluated to assess the original hydrocarbons in place for each reservoir, material balance results have been compared to the current reservoir pressures to validate the reported gas production and gas re-injection values over time, and to obtain the current in place volumes. Based upon the current gas in place and the reservoir pressure profiles, a well development program was prepared to support the production plan. As part of the reservoir assessment it was found that the current in place gas/liquid volume in the reservoir does not support the clients originally proposed production plan. Hence as a result of these feasibility study findings the client postponed the offshore development and NGL recovery facilities revamp scopes.

Overall Fluor has been able to successfully and effectively coordinate the different interfaces between the client´s intended production plan and availability of data of the existing reservoirs to the reservoir engineering consultant and from the output of the reservoir engineering study back into the data needs for the required production to identify the potential offshore development and downstream NGL processing facilities’ revamp.

- Reservoir Engineering

Session Introduction

Ralph-Uwe Dietrich

German Aerospace Center (DLR), Germany, Stuttgart

Title: Synthetic jet fuel from renewable energy sources for sustainable aviation

Biography:

Dr.-Ing. Ralph-Uwe Dietrich leads the research area Alternative Fuels at the Institute of Engineering Thermodynamics at the German Aerospace Center (DLR) in Stuttgart. He is responsible for the research group on techno economic and ecologic evaluation of alternative fuels for aviation and global transport. He received his PhD in Engineering at the Technical University Clausthal in 2013 as a Scientific coworker at the Clausthaler Umwelttechnik Institute (CUTEC-Institut GmbH). Before that, he got 15 years of project manager experience at different enterprises (SME and Fortune 500) of the process and automation industry.

Abstract:

Advanced technologies, optimized operation and infrastructure are not sufficient to achieve the CO2 mitigation goals agreed on for the aviation sector. Carbon neutral alternative liquid fuels are required to fill the gap towards a carbon-neutral growth from 2020 on. The Power-to-Liquid process is one option to produce synthetic jet fuels from renewable energy. The technical and economic performance of production processes based on renewable electricity and CO2 was investigated and evaluated.

Hydrogen can be generated by water electrolysis from fluctuating renewable power sources. Together with CO2 – e.g. sequestrated from industrial resources – the reverse water-gas-shift reaction forms syngas. The Fischer-Tropsch synthesis produces long chained hydrocarbons from syngas. Downstream product separation and upgrading generates gasoline, jet fuel and diesel. Another process concept is based on high temperature co-electrolysis of steam and CO2 producing synthesis gas at high temperature and pressure.

The process performance is evaluated via flowsheet simulation models and pinch point analyses comparing the Power-to-Fuel efficiency as well as carbon conversion into liquid fuels. A baseline Power-to-Fuel efficiency of 44 % for the concept based on water electrolysis can be increased to 60 % using the co-electrolysis concept. The baseline carbon conversion of 73 % grows to 98 %. The sensitivity of various operation conditions was analyzed.

A cost analysis based on market data and equipment factors was performed for the investment year 2014. Employing stationary power input of 105 €/MWh, production costs of 3.38 €/kg were found for the water electrolysis concept. The production costs of the co-electrolysis concept compare to 2.83 €/kg. The sensitivity of the electrolyzer capital cost and electricity prices were analyzed and their effect on the production costs will be presented.

Investment and operating costs to fill the gap towards carbon-neutral air transport growth from 2020 on can be predicted based on 2014 costs and technology status. A comparison to other renewable jet fuels regarding land use, feedstock potential and economic measures will be provided.

Kjeld Bokstijn

employed by Fluor as a process director working on projects mainly in the chemical, petro-chemical, refining and power generation area

Title: Integrated consulting services for rich gas production plan from mature fields

Biography:

Kjeld Bokstijn is a process engineer that has been active in the industry over the last 22 years, working in production and engineering functions in The Netherlands, the United States and Spain. He holds a BSc. and MSc. in Chemical Engineering and is currently employed by Fluor as a process director working on projects mainly in the chemical, petro-chemical, refining and power generation area. However due to the interfaces between the gas plant and the petrochemical units consuming the NGL feedstock from these, he has become involved in this NGL recovery and gas-production feasibility study. Fluor´s Energy and Chemicals division, an international engineering contractor, is involved in all these areas from upstream, midstream, downstream, petrochemical, chemical and energy business and as such can bring together multi-functional teams to work on these diverse projects offering these kind of interesting assignments to their personnel.

Abstract:

Fluor was approached by a client requesting a feasibility study for a rich gas field development and debottlenecking the offshore and downstream NGL facilities. Fluor is primarily involved with gas/oil production, transportation, and gas processing/NGLs facility design and does not perform reservoir assessments in-house. In this case, Fluor and the client worked out an integrated solution with a subcontracted reservoir engineering effort to assess current in place gas/liquid volume that could be produced from the fields to support the desired gas feed rate for the offshore and onshore NGL facilities our client wanted to debottleneck.

The reservoirs have been evaluated to assess the original hydrocarbons in place for each reservoir, material balance results have been compared to the current reservoir pressures to validate the reported gas production and gas re-injection values over time, and to obtain the current in place volumes. Based upon the current gas in place and the reservoir pressure profiles, a well development program was prepared to support the production plan. As part of the reservoir assessment it was found that the current in place gas/liquid volume in the reservoir does not support the clients originally proposed production plan. Hence as a result of these feasibility study findings the client postponed the offshore development and NGL recovery facilities revamp scopes.

Overall Fluor has been able to successfully and effectively coordinate the different interfaces between the client´s intended production plan and availability of data of the existing reservoirs to the reservoir engineering consultant and from the output of the reservoir engineering study back into the data needs for the required production to identify the potential offshore development and downstream NGL processing facilities’ revamp.

Sun ke

China University of Petroleum, China

Title: The application of architectural elements analysis in characterizing complex reservoir: A case study of Yong’an town oil field, Dongying Sag, Bohai Bay Basin, China

Biography:

Sun ke, PhD. candidate, engaged in petroleum geology research, Department of Geology, College of geological science and technology, China University of Petroleum, No.66 Changjiang West Road, Huangdao District, Qingdao,China,

Abstract:

As the exploration and development of oil and gas fields gets deeper and deeper in our country, characterization of complex reservoir has become one of the most important research fields. The characteristics of complex reservoir are that rock composition is complex, space structure is complex, kind of reservoir space is various, heterogeneity is strong, physical properties is changeful et al. In view of the above characteristics, there are three problems in traditional reservoir characterization methods which is about gradation, structure and genesis. That architectural elements analysis put forward offers method and idea for solving the above problems. Compared with traditional reservoir characterization methods, the advantages of architectural elements analysis mainly display in three points: first, it can be applied to divide high frequency level of reservoir; second, it can be applied to analyze complex structure of reservoir; third, it can be applied to explain the genesis of reservoirs. The Application of architectural elements analysis in characterizing complex reservoir need to pay attention to the applicable condition of the method, the choice of the basic research unit and the relationship between architectural elements and pay zone units. This paper takes Es26 of mouth bar which belongs to the Yong3-1 fault block of Yong’an town oil field in Dongying Sag as example, combining with the advantages of architectural elements analysis and problems that should be noticed, thoroughly studies the issues on the division of bounding surface, reservoir sedimentary genesis and the distribution characteristics of oil and water, and comes to the conclusions: the original 61 layer could be divided into six times accretions of mouth bar(architectural element of 3 level),the dip angle of mouth bar accretions is between 2~3°; six times accretion of mouth bar had the characteristics of retrogradation from west to eastï¼› the oil and water distribution of 61 layer was mainly controlled by accretion of mouth bar.

Faraj Ahmad AL-Sulaiman

chief geologist in the Field division of petroleum engineering department for the North Oil Company, Ministry of oil, Kirkuk, IRAQ

Title: Geologic evaluation of Kirkuk underground storage project NE Iraq

Biography:

Faraj A. Al Suleiman, is chief geologist in the Field division of petroleum engineering department for the North Oil Company, Ministry of oil, Kirkuk, IRAQ, He received his BSc degree from Mosul University in general geology in 1982, and received MSc and PhD degree in structural geology from Baghdad university, in 1989 and 1998 respectively, since 2000 he joined North oil company as supervisor for logging operation and interpretation. In addition to work in North Oil Company, he lectured in kirkuk and Tikrit universities.

Abstract:

Storage of liquids and gases in solution mined salt caverns was reportedly first in Canada in the early 1940 s during world war. Storage in the salt caverns of liquid petroleum gas (LPG) and other light hydrocarbons spread rapidly in the early 1950s in North America and several European countries. Storage of crude oil reportedly occurred first in England, also in 1950s during the Suez crisis. Natural Gas Storage followed the storage of liquid hydrocarbons by about decade in the U.S.A. and Canada,(Dreyer,1920).Kirkuk underground storage project locate on the southern west limb of Kirkuk anticline near Kirkuk city, North Iraq,(fig-1).In 1978 eight wells were drilled for the purpose of LPG storage ,five wells of them(2,5,6,7,8) were selected for leaching operations as the thickness of salt layer in these wells was suitable to create cavern of salt and economical size.

Geologic evaluation of the Kirkuk underground was conducted by comparison of the geometric properties of the cavities derived from two surveys running during 1989 and 2015.the vertical cross sections of the cavities show that most cavities have show that most cavities have irregular shape because of the presence of impurities in the salt bed that cause different leaching velocities in different directions .the relationship of the cavity roof with tilted salt bed was Image

Diji, Chuks. J.

CPEEL, University of Ibadan, Nigeria

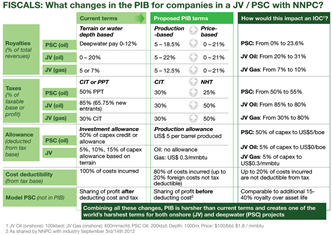

Title: Comparative Analysis of Nigeria Petroleum Fiscal Systems Using Royalty and Tax Optimization Models to Drive Investments.

Time : 11:40-12:15

Biography:

Dr. Diji obtained a PhD in Mechanical Engineering from the University of Ibadan in 2008, Masters of Science degree (MSc) in Mechanical Engineering from the University of Ibadan in 1997 and a Bachelors of Science (B.Sc) from the Obafemi Awolowo University (Formerly University of Ife) in 1987. He has a professional postgraduate qualifying Diploma in Management Consultancy practice and Organizational Transformation of the International Professional Managers Association (IPMA – Uk). He is currently a senior lecturer and ag. Head of department of Mechanical Engineering, University of Ibadan, Nigeria. I currently teach courses in Thermo – fluids, material science, production technology and entrepreneurship as well as energy studies at both undergraduate and postgraduate level. He also serves as an associate lecturer in two major academic Centre’s of the University of Ibadan: Centre for Sustainable Development (CESDEV) and the Centre for Petroleum, Economics, Energy and Law (CPEEL). His core competences are in energy studies, environment and small business development.

Abstract:

The adoption of any petroleum arrangement - concessionary or contractual - is a financial issue that is centered on how costs are recovered and profits divided, which is at the heart of taxation and economic rent theories. Hence countries are expected to make the tax system attractive for the IOCs in order to encourage inward investment. The effectiveness of any petroleum arrangement depends largely on the attractiveness of its underlying tax regime which, in turn, depends on the effectiveness of its design and implementation. The uncertainty created by the non-passage of the proposed Nigeria Petroleum Industry Bill (PIB) over the years has continued to impede investments in the oil and gas sector in Nigeria. Oil producers Trade Section (OPTS) and other stakeholders in the sector in Nigeria have expressed concerns over the federal government’s intention to change the laws governing the oil and gas industry including the fiscal terms. The aim of the study is to critically examine whether the Nigerian petroleum tax system is appropriately designed and effectively implemented to achieve the benefits the country desires from its petroleum taxation arrangements. The study reviews the current and post PIB upstream fiscal regimes and undertook a comparative examination of Nigeria’s fiscal regime against selected world fiscal arrangements. The study also determined how Nigeria’s fiscal regime holds up against key features of importance to government and prospective investors, which include degree of stability, flexibility, neutrality and how the regime distributes the burden of risk between the resource owner and the oil companies. The study concluded from preliminary studies that there is a correlation between fiscal terms (tax and royalty) and various profitability indexes (DCFR, PIR, AVP, PVP, MCI & payout). The global comparative analysis result also shows that Nigeria fiscal terms (pre & post PIB) are outside the competitive window and will invariably discourage foreign direct investments.

Feridun Demir

Associate Professor of Chemical Engineering at the Osmaniye Korkut Ata University in Osmaniye, Turkey

Title: Petroleum sector in Turkey

Time : 12:15-12:50

Biography:

Feridun Demir obtained his PhD degree from the Department of Chemical Engineering at the University of Florida, and is currently an Associate Professor of Chemical Engineering at the Osmaniye Korkut Ata University in Osmaniye, Turkey. He has expertise in chemical reaction engineering, process control, and colloidal hydrodynamics. He has developed a feedback control model with a variable and large dead-time for a wastewater treatment plant, and his study has made significant contributions to chemical kinetics, control engineering, and computer simulation. Dr. Demir has also worked with the Engineered Particulate Systems group of the Engineering Research Center at the University of Florida, and investigated colloidal hydrodynamic behaviors of fine particles and surface properties. He has recently been working on the synthesis of conductive polymers, water treatment, simulation of differential equations, and recycling of petroleum wastes.

Abstract:

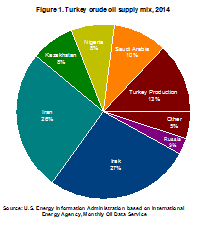

Among OECD countries, Turkey has the highest rate of increase in energy demand since 2010, and it is noteworthy that it depends on energy imports to a large extent. The continuation of the decline in oil prices in 2015 has enabled Turkey to reduce its oil and natural gas import costs as well as other oil and natural gas importing countries. The crude oil supply of Turkey in 2014 is shown in Figure 1.

In 2015, Turkey produced approximately 51 thousand v/d crude oil per day. Whereas, 796 thousand v/d crude oil was consumed; import of crude oil at 503 thousand v/d level and 242 thousand v/d imports of finished goods were realized. Compared with the year 2014, while imports of finished products showed a decline, crude oil imports and crude oil consumption increased. In 2015, the total consumption rate of domestic crude oil production was 6.4%. The consumption rate of Turkey’s domestic natural gas production in 2015 was the lowest in the last decade and realized as 0.8%. In other words, Turkey's import dependency rate for petroleum is 93.6%, and natural gas import dependency rate is 99.2%. In 2015, the distribution of petroleum imported by Turkey according to the source countries has changed considerably compared to the year 2014. It is observed that in 2014, 90% of the imports are made in only six countries, while in 2015 the source country balances have changed. Iraq ranks first with 29%, Russia second with 18%, Iran third with 14%. Compared to 2014, the rate of oil imports from Iran and Saudi Arabia has fallen, while the share of Russia and India has risen considerably. When we look at the source countries where oil is imported in 2015, the most noteworthy point is the diversity of countries where oil is imported at low levels.

Prakash K Nair

University of Bradford, UK

Title: Impact of Impurities on Formation of Carbon-Dioxide Hydrates

Time : 12:50-13:15

Biography:

Prakash Kumar Nair is currently a MEng student studying Chemical Engineering at the University of Bradford. Residing in Doncaster, Prakash has an extensive interest in the oil and gas industry and CO2 capture and storage. The interest in the latter lead to Prakash taking on the Masters project entitled ‘Impact of Impurities on Formation of Carbon-Dioxide Hydrates’. During the course of this project, Prakash has had his work accepted for a poster presentation at the annual conference ‘ChemEngDayUK 2017’ and an oral presentation at the 6th International Conference on Petroleum Engineering.

Abstract:

The continued rise of CO2 emissions threatens life on Earth, through warming the planet. Carbon Capture and Storage (CCS) is an effective method in reducing CO2 emissions, thus over time, inhibiting the effect of global warming. One of the major challenges that face the transportation process, an intermediate stage between capture and storage, is potential flow assurance issues, especially hydrate formation due to the presence of impurities such as N2 and H2O. If the conditions within the pipeline are at a high pressure and low temperature, hydrates could form. Hydrate formation, which is the physical combination between a gas molecule and water molecules, could cause pipe blockage and therefore, stop the high-CO2 mixture being transported to its storage location.

This study aimed at investigating the impact of impurities on the formation of CO2 hydrates, whilst simultaneously, considering the vapour-liquid equilibrium (VLE) phase envelope. Initially, a sensitivity analysis on binary and tertiary systems was conducted, based on the impurities most commonly encountered in CCS. Where from here, investigation into two case studies (Cortez and Sheep Mountain Pipeline) was conducted. The results from the binary analysis showed H2S caused a significant expansion of the hydrate stability zone (HSZ). The presence of the impurities, COS, SO2 and NH3, caused the opposite effect to what was found with H2S. Each impurity caused an effect on the VLE phase envelope with H2 and N2 causing the most significant expansion. The tertiary system sensitivity analysis showed there was a clear interaction between H2S with Ar, O2 and CH4. Analysis into the case studies showed the presence of H2S reduced the hydrate formation pressure thus increasing the likelihood of hydrate formation. This was proven to be counteracted with the presence of either COS, SO2 or NH3, where they increased the hydrate formation pressure.